Only by combining

these basics with an unrelenting responsibility to improve, can we move to a successful future.

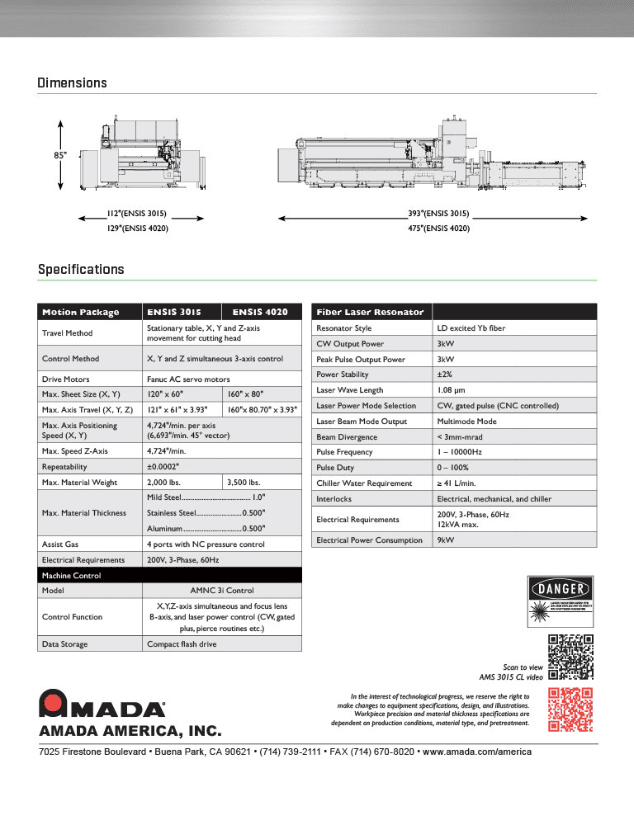

LASER CUTTING TECHNOLOGY

Laser cutting systems utilize the latest advances in laser manufacturing technology that enable customers to maximize their productivity and profitability. The laser technology in AMADA laser cutting machines allows for high cutting speeds and the flexibility to process a wide range of materials like aluminum, steel, copper, and brass resulting in Process Range Expansion (P.R.E.).

- No spatial cavity in the oscillator

- More efficient processing

- 1.08 nm wavelength: better beam absorption

- Cuts copper, brass, and titanium

- No mirrors in the laser source

- Simplified laser generation

ON-DEMAND LASER CUTTING SERVICE

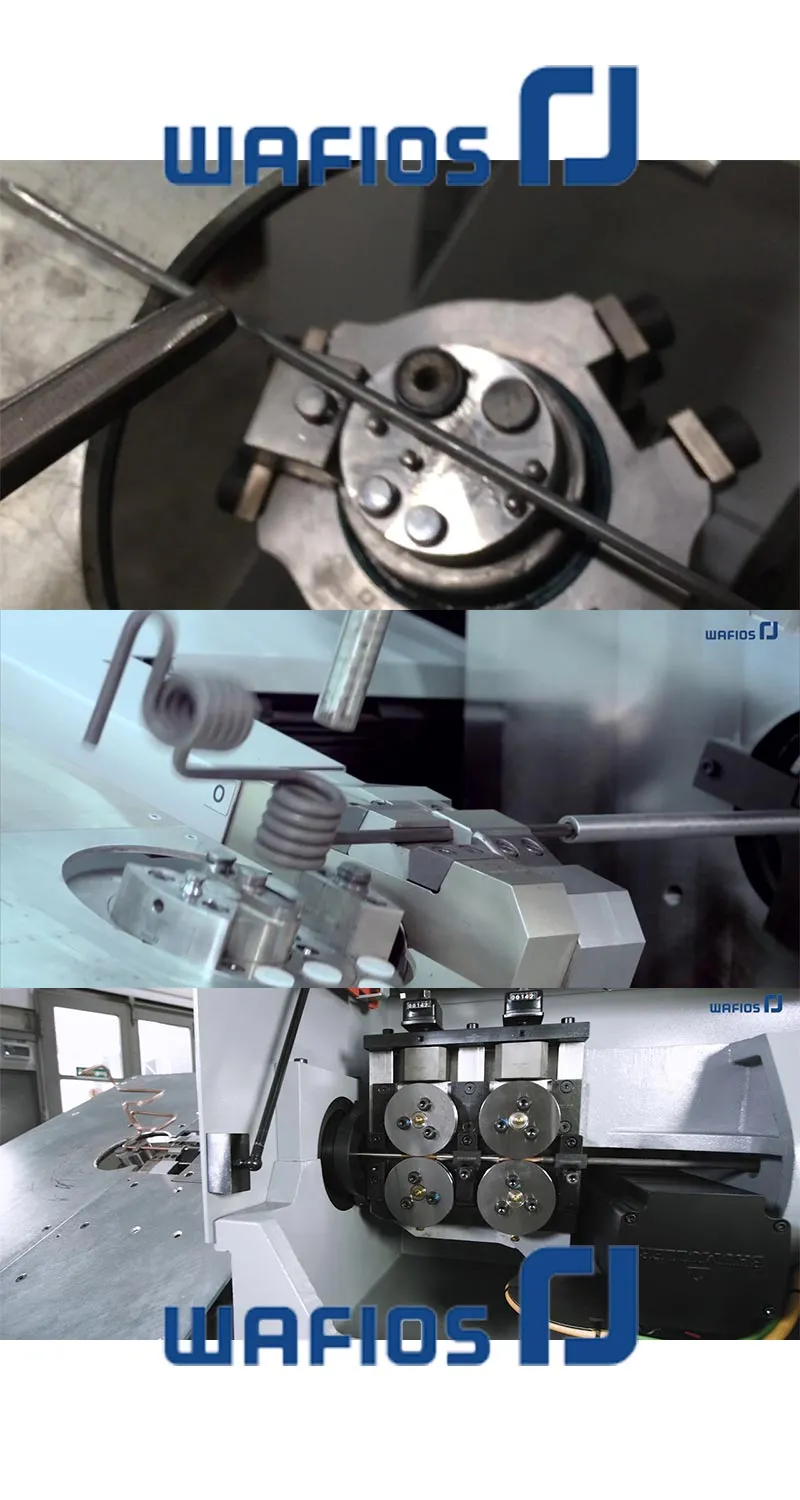

bending-and-coiling-technology

The WAFIOS wire bending machines process soft wire from 1.5 mm to 16 mm and spring wire from 1.5 mm to 10 mm into two- or three-dimensional bent parts. Although some of these parts feature coils and therefore provide a spring function, they are not classic extension or compression springs. If such springs are to be produced in large numbers, manufacturers will find alternative solutions in the Reutlingen-based machine builder’s range of torsion spring coiling machines.

OUR PARTNERSHIP WITH US CUSTOMER ALLOWED OUR SALES TO GROW $4.2 MILLIONS IN 2019

SHEET METAL CUTTING SHEARS

A good machine ultimately helps you be more productive. You need to make more parts in less time. Accurl shears are designed to give you the highest level of production without compromising safety or breaking your budget. And our shears are so simple to use; you'll be amazed how fast your bottom line will grow!

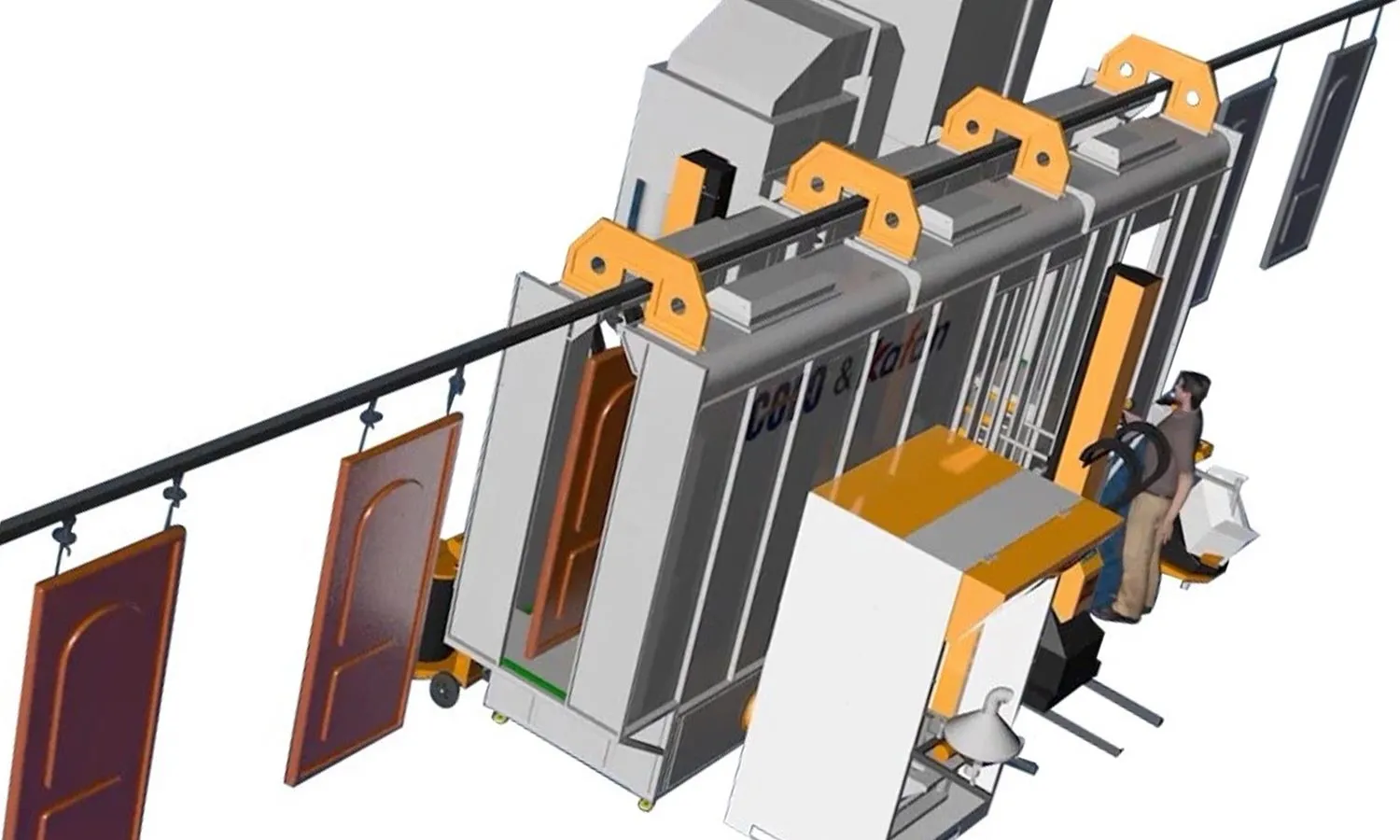

POWDER COAT PAINT LINE

Our powder coating line is adapted to treat various types of industrial products. It ensures optimum surface resistance. The resistance depends on two points: the processes of surface treatment before powder application and the type of powder used with the possible application to higher thickness. The powder coating can be applied on products that resist high temperatures of polymerization; in general, it means that each type of metal surface can be powder coated.

In the typical metal finishing process, the alkaline cleaning tanks are first in line and take the bulk of the dirty load

It is critical in the metal finishing process

The process of phosphating is typically listed as a conversion coating because the process involves metal removal as part of the reaction.

Method employed to dry parts

High temperatures are required to get the powder to liquefy and flow.

Per Hour

PLATE BENDING PRESS

Sectioned jaws allow working with segmented tools that offer high flexibility and easy loading and unloading with a single operator. Accepts conventional tools, precision tools, and Wila American tools from high precision with the Safety-Click® button for safe vertical filling.

Capacity